Electrical Signals Never Lie.

Electric Signature Analysis that reveals hidden faults early – helping you prevent failures,

reduce downtime, and protect critical industrial and energy assets.

+

17603

Assets Monitored Worldwide

+105

M€

in Savings

+

13

Years of Experience

+

42

Active Countries

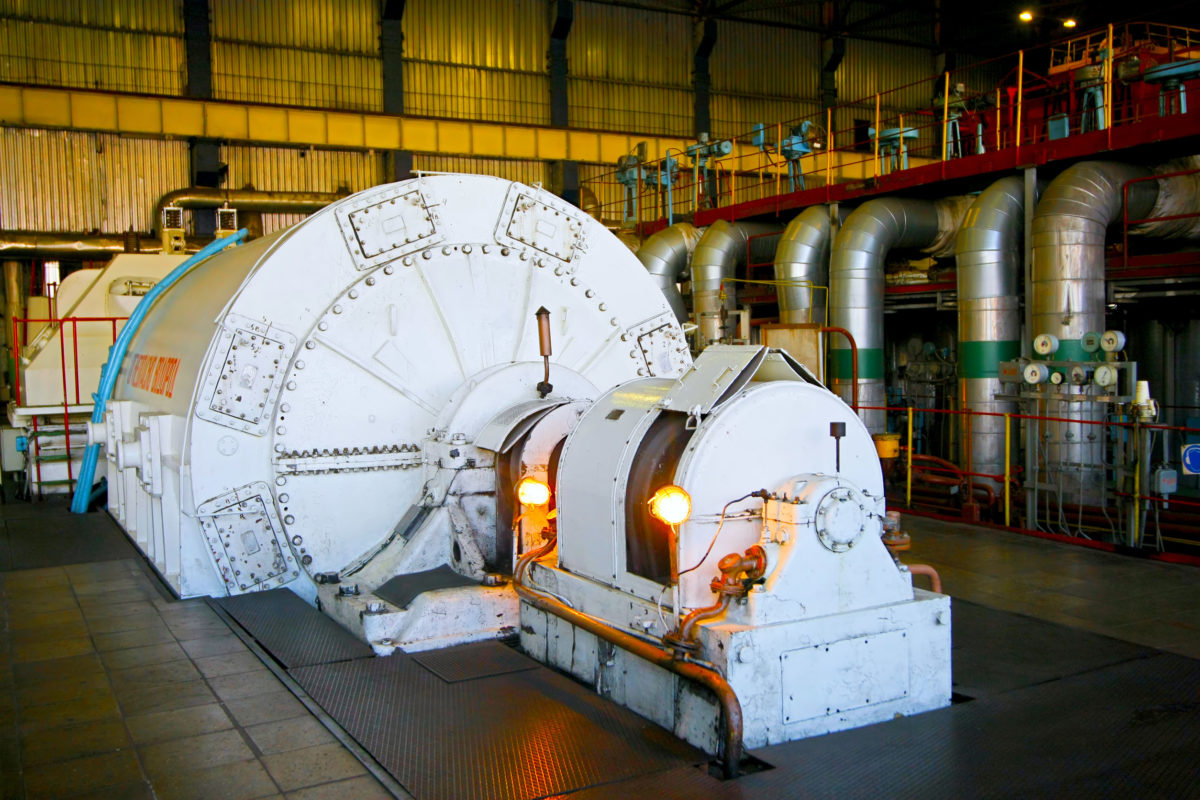

Enging provides Electric Machines Condition Monitoring in any industrial process and electric asset.

No matter its location, typology or voltage level.

Exclusively using electric variables and with a non-invasive technique, Enging has the capacity to pinpoint degradations in electric assets several months before it becomes a catastrophic fault.

Rotating Machines

Transformers

Power Converters

Solar PV Farms

Wind Turbines

Battery Storage

Our Solutions

Discover Enging’s solutions designed to extend asset lifetime and enhance performance.