$55k

SAVINGS

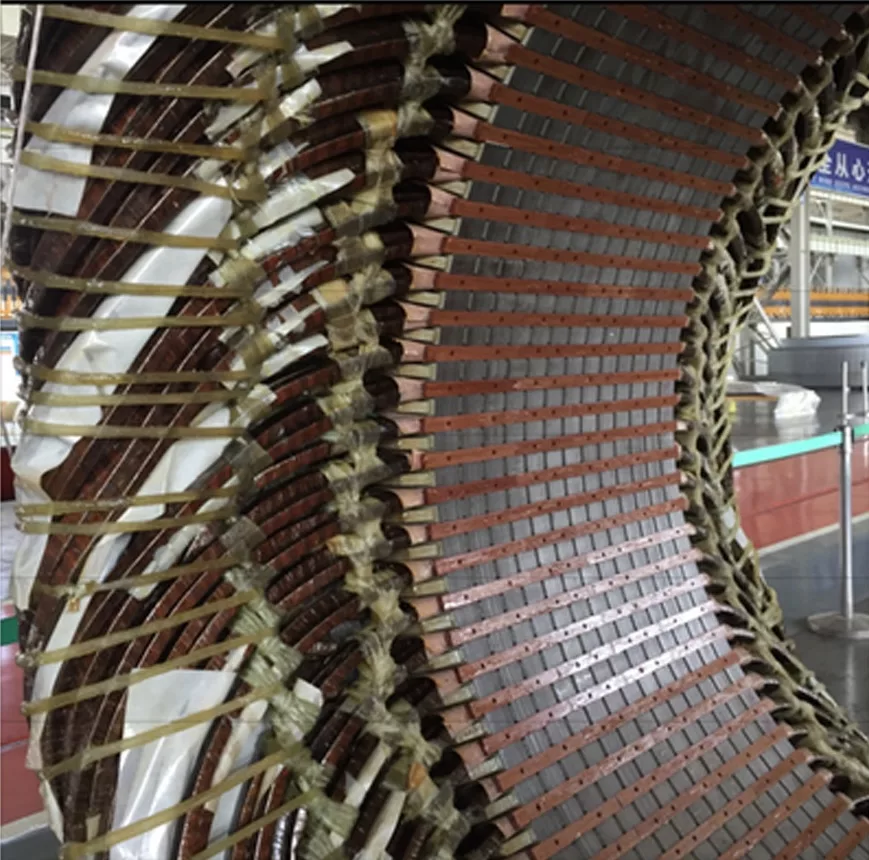

In a 24/7 critical compressor, Enging detected an abnormally high spectral component at 896 Hz, causing a high-frequency ripple in the motor phase currents.

By validating the motor’s internal design with the client, it was confirmed that this frequency was linked to internal stator winding vibration — a fault that often goes unnoticed until severe damage occurs.

With early detection powered by Electric Signature Analysis (ESA), the issue was identified before it escalated, ensuring reliability and continuous operation.

INDUSTRY

Petrochemical

ASSET

Compressor

PROBLEM

Internal Stator Winding Vibration

AVOIDED

Major Motor Failure