Main Advantages

Electric detection of motor failures through advanced Electrical Signature Analysis (ESA).

Physics-based algorithms supported by AI for superior diagnostic accuracy.

Non-invasive installation using current and voltage transformers.

Seamless integration with SCADA, cloud or on-premise platforms.

Continuous, real-time health monitoring with zero operational impact.

Reduction in downtime, repair costs and safety risks.

Discover our Solutions

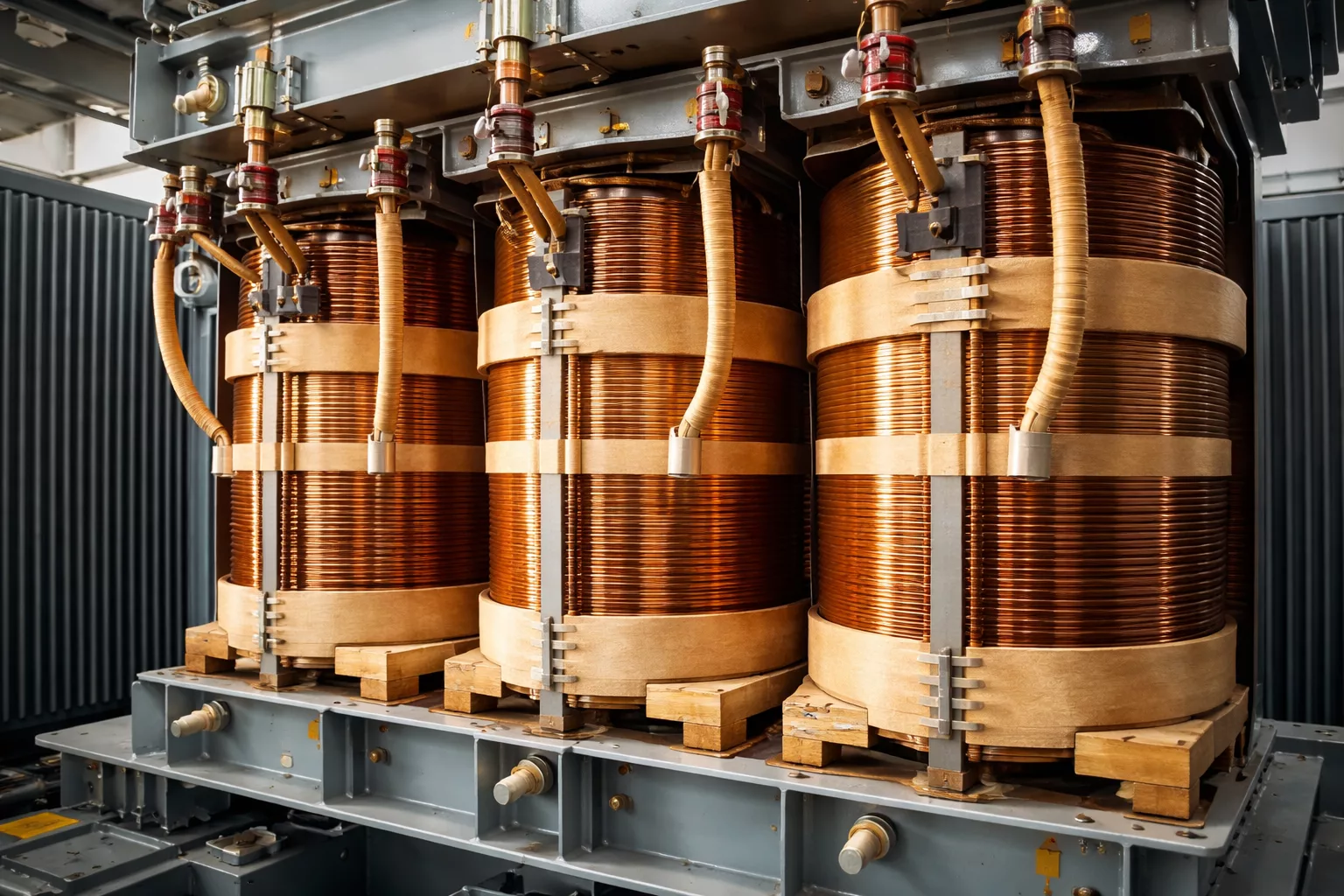

PreditTransf

Transformers are critical assets in any power or industrial system, and failures can cause costly downtime and long replacement delays. Early detection of faults is essential to ensure reliability and avoid major impacts on operations.

PreditTransf enables real-time, non-invasive monitoring of transformer electrical, magnetic, and mechanical conditions, identifying abnormalities at an early stage so maintenance can be planned and unplanned outages avoided. It also helps prevent localized issues from spreading, reducing repair costs.

This solution uses an innovative deterministic algorithm that relies solely on electrical variables—no historical data required—offering significant advantages over traditional monitoring techniques.

Applications

The solution PreditTransf can be applied to any transformer in an industrial installation, power plant or electric grid:

- POWER TRANSFORMER

- DISTRIBUTION TRANSFORMER

- GROUNDING TRANSFORMER

- OPEN-PHASE DETECTION (Nuclear Power Plants)

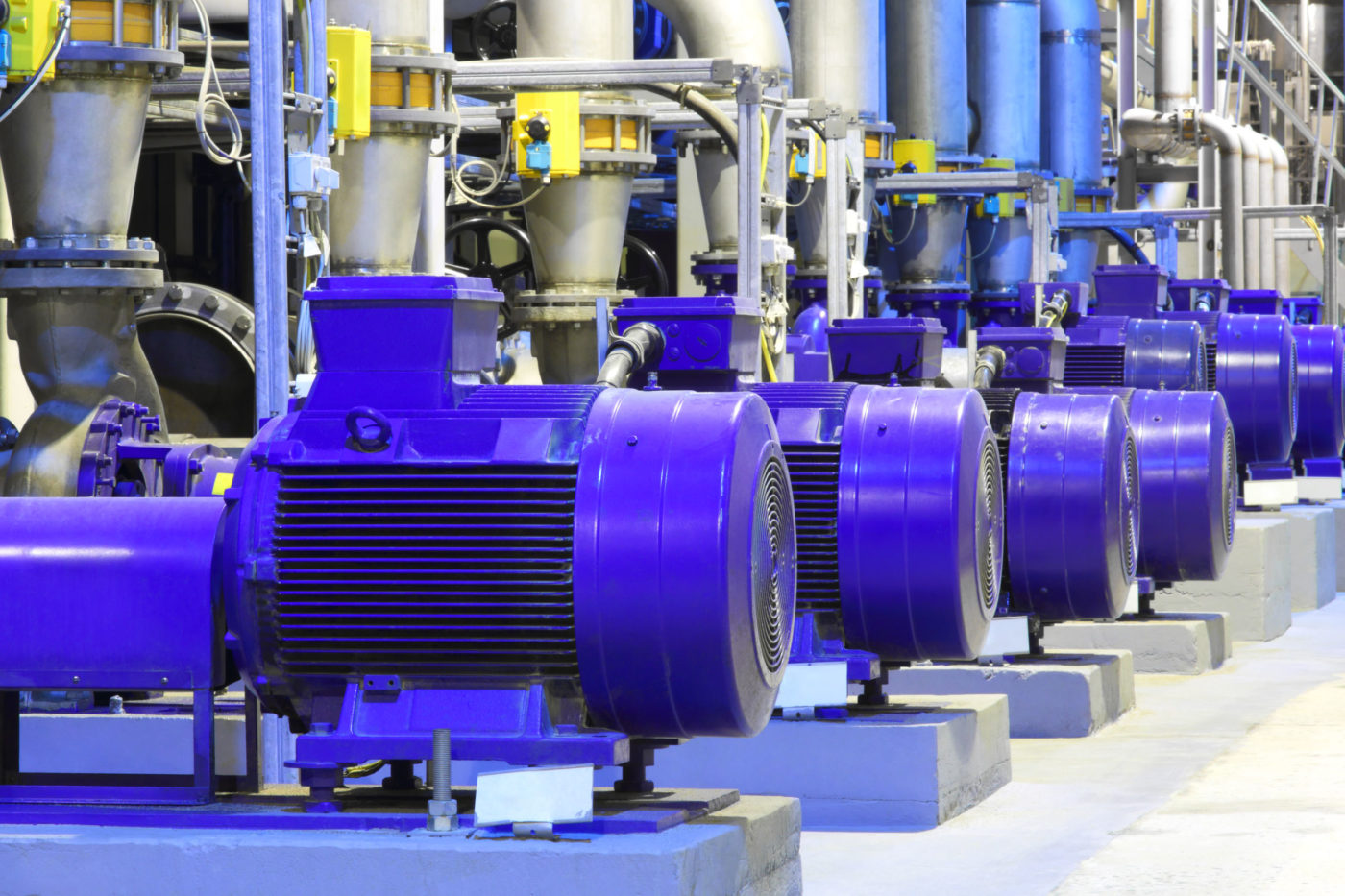

PreditMot

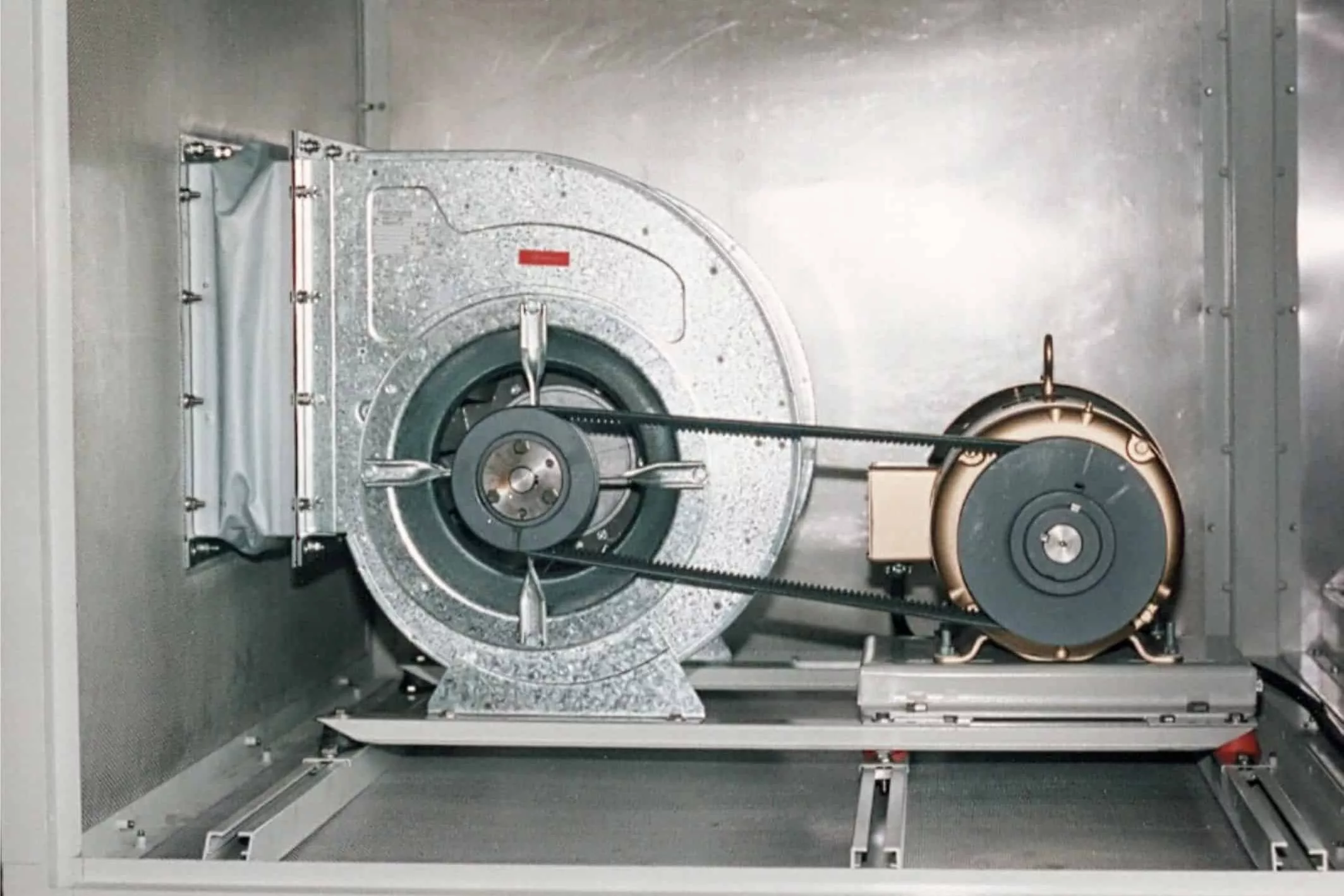

Electric motors are essential to industrial operations, and failures can lead to significant financial losses and safety risks. PreditMot provides advanced diagnostic capabilities to detect common motor faults at a very early stage, enabling truly predictive maintenance.

With continuous remote monitoring accessible from anywhere, PreditMot evaluates fault severity in real time using only electrical measurements—ideal even for motors with limited physical access, where vibration or temperature-based methods cannot be applied. All operating and fault information is presented clearly through a web platform for each asset.

Based on an innovative deterministic algorithm that requires no historical data, this approach offers significant advantages over traditional motor monitoring techniques.

Applications

The solution PreditMot can be applied to low and medium voltage three-phase motors, applied to several applications, like:

- Fans

- Pumps

- Paper Machines

- Conveyors

- Compressors

- Mills

- Electric Vehicles

- Chillers

- Elevators

- HVAC

- Motogenerators

- Crushers

- Among other type os applications

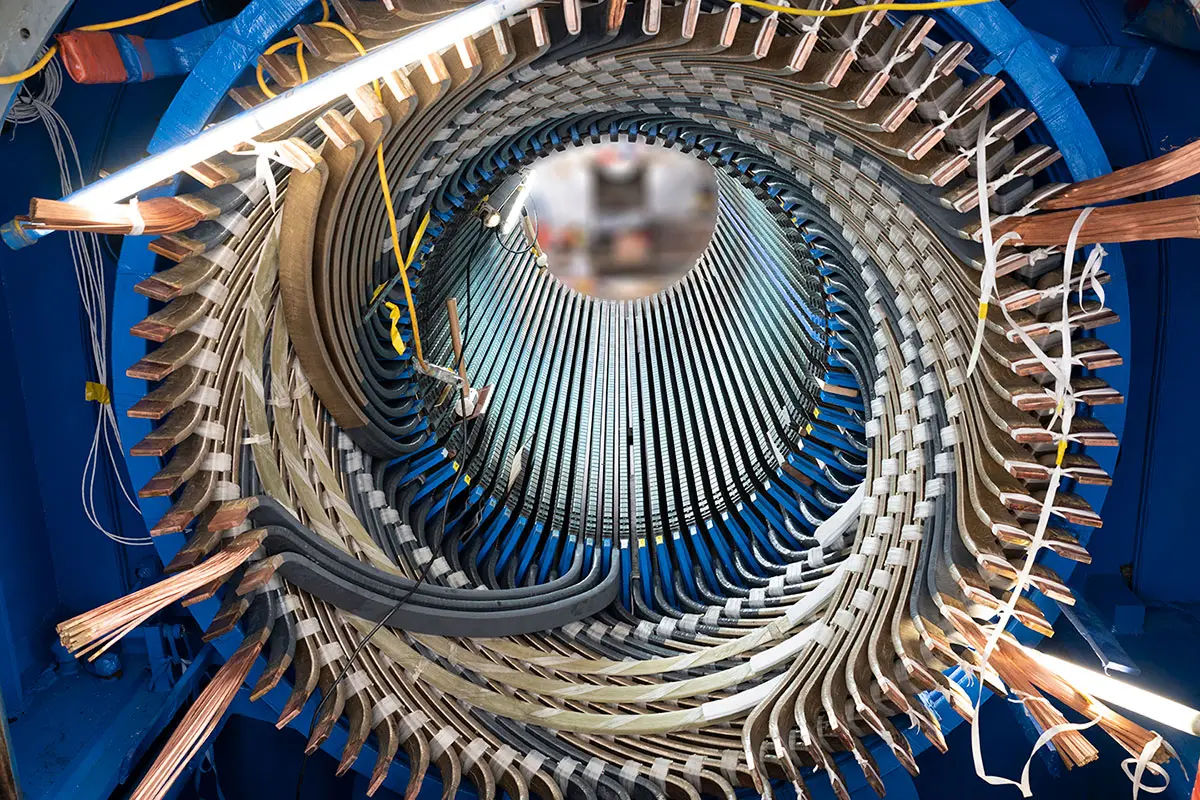

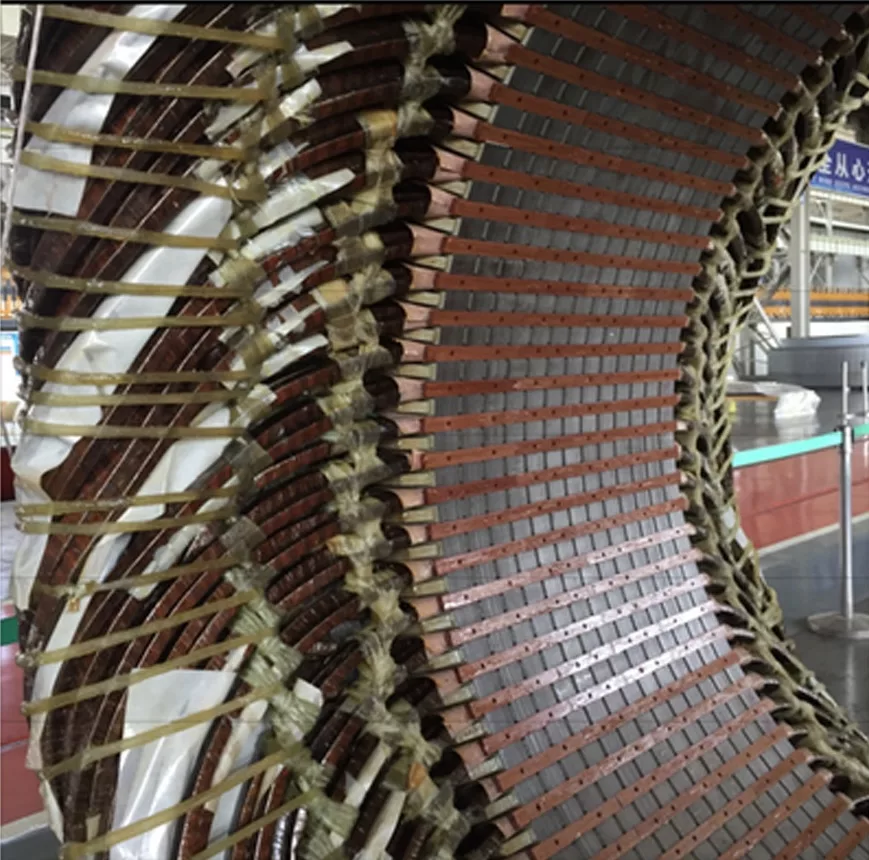

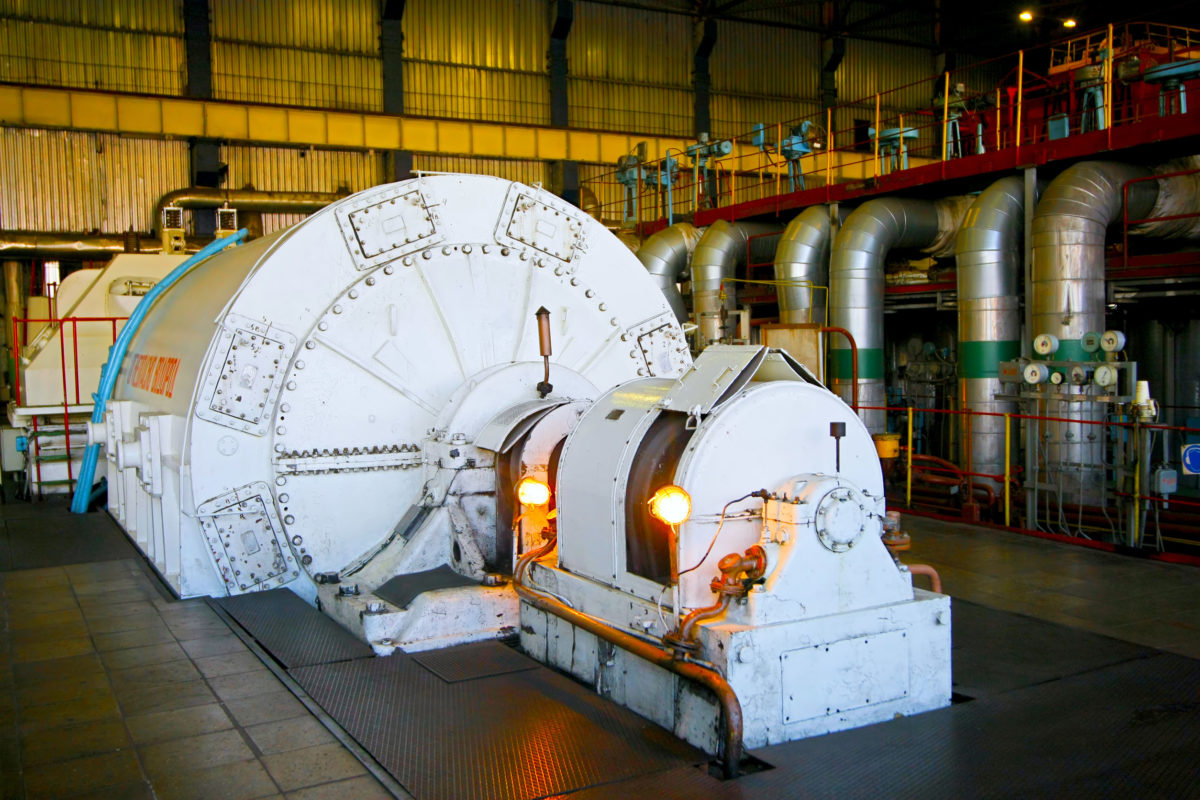

PreditGen

PreditGen uses state-of-the-art diagnostic techniques to perform the detection of the frequently faults and evaluation of the faults severity in this type of equipment. It is an advanced solution that allows to perform predictive maintenance actions in low, medium or high voltage three-phase Generators, with the capability to detect failures in system’s components in a very early stage. It is based on a continuous remote monitoring system, permanently accessible from any location with internet access, and which allows users to monitor and intervene in real time. Based on the easily measurable electrical quantities acquisition, this approach can be used in several applications, including those where physical access to the generators is limited. Under these conditions, typical monitoring techniques based on vibration and temperature analysis cannot be applied.

All the relevant data related to the generator’s operating condition is presented to the user in a web platform, showing the fault degree and power quality parameters of each asset, individually.

This solution is based on an innovative deterministic method completely different from traditional techniques, based on a deterministic mathematical algorithm and using only electrical variables as inputs, with no need of historical data.

Since it is based on the measurement of electric variables, this approach presents several advantages when compared to traditional techniques.

Applications

The solution PreditGen can be applied to low, medium or high voltage three-phase generators, applied to several applications, like:

- Hydro

- Wind

- Thermal

- Solar

- Biomass

- Gas

- Among other type of applications

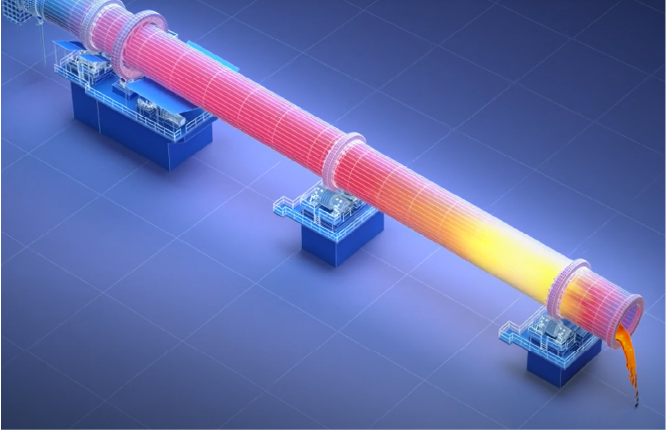

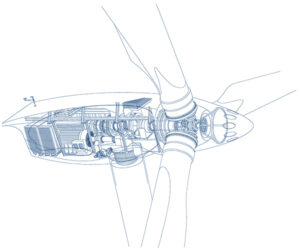

PreditWindT

The real-time monitoring system for Wind Turbines, PreditWindT has developed for the real-time monitoring of the main components of the power module in wind turbines, namely the generator, power electronics (power converter and soft starter) and distribution transformer, that will allow to the operators to apply preventive maintenance strategies instead of corrective actions, with increased availability and significant operation cost savings.

PreditWindT uses an innovative fault diagnostic algorithm that integrates the most recent advances in the field of electric Asset Performance Management. With additional capabilities to those of a simple vibration analysis, the Enging algorithm makes a powerful electric signature spectral and time analysis for detection of faults and abnormal operating conditions.

The monitoring system uses state-of-the-art diagnostic techniques developed by Enging, to perform the detection of frequent faults and the evaluation of the fault´s severity level in this type of assets. It is an advance solution that allows to perform predictive maintenance actions in the main components of the power module in wind turbines.

The algorithm also combines the most recent scientific innovations in this sector, allowing to discriminate component faults from load oscillation conditions due to wind fluctuation.

Applications

The solution PreditWindT can be applied to several wind turbine characteristics:

- Wind Turbine with Squirrel Cage Induction Generators

- Wind Turbine with Wound Rotor Induction Generator

- Wind Turbine with Doubly Fed Induction Generator

- Wind Turbine with Permanent Magnet Synchronous Generator

- Wind Turbine with Electrically Excited Synchronous Generator

- Among others wind turbines

PreditPV

The real-time monitoring system for solar photovoltaic farms, PreditPV has a disruptive technique to monitoring some critical assets, namely Solar Inverters and Distribution Transformers.

Facing the Solar growing market, PreditPV aims to offer PV plants’ owners an extremely accurate predictive maintenance solution using a completely non-invasive approach, thus preventing costly corrective maintenance actions and unexpected stoppages with huge non-production costs.

PreditPV is based on a real-time monitoring system that can be accessible from any location with internet access, allowing the users to view real-time data and act immediately under the presence of an early fault. Since it is just based on the measurement of electrical variables, this approach is much more advantageous when compared to the traditional techniques.

The diagnostic algorithm only requires the voltage of the solar inverter and the current signals from the both transformer’s sides (medium voltage and low voltage). These signals can be easily measured by non-invasive voltage and current transducers, installed in each phase conductor.

All the relevant data related to the solar inverters and transformer’s operating condition is presented to the user, showing the solar inverter and transformer’s fault degree and power quality parameters.

Applications

The solution PreditPV can be applied to monitor assets at Solar Photovoltaic power plants

PreditBS

The real-time monitoring system for battery storage systems, PreditBS has a disruptive technique to monitoring some critical assets, namely Inverters and Distribution Transformers.

Facing the renewables growing market and the need for energy storage, PreditBS aims to offer battery storage’s owners an extremely accurate predictive maintenance solution using a completely non invasive approach, thus preventing costly corrective maintenance actions and unexpected stoppages.

PreditBS is based on a real-time monitoring system that can be accessible from any location with internet access, allowing the users to view real-time data and act immediately under the presence of an early fault. Since it is just based on the measurement of electrical variables, this approach is much more advantageous when compared to the traditional techniques.

The diagnostic algorithm only requires the voltage of the inverter and the current signals from the both transformer’s sides (medium voltage and low voltage). These signals can be easily measured by non-invasive voltage and current transducers, installed in each phase conductor.

All the relevant data related to the inverters and transformer’s operating condition is presented to the user, showing the inverter and transformer’s fault degree and power quality parameters.

Applications

The solution PreditBS can be applied to monitor electric assets at battery storage systems.